Page 1 of 1

How to use a relay in a breadboard.

Posted: Thu Dec 04, 2008 7:43 am

by laeeq

I want to use a relay NAIS, HX2-4.5-H12 in a bread board. But relay pins are completely incompatible with breadboard holes.

Is this a common problem?

Is there a standard solution?

Thanks in advance.

Re: How to use a relay in a breadboard.

Posted: Thu Dec 04, 2008 7:58 am

by Bigglez

laeeq wrote: I want to use a relay NAIS, HX2-4.5-H12 in a bread board. But relay pins are completely incompatible with breadboard holes.

Is this a common problem?

Yes! Breadboards are typically on a 100mil (0.1 inch)

grid, as are many electrical and electronic components.

Newer parts (particularly SMD/SMT) are not on any

standard pitch, and smaller parts are being released

every month.

Older and particularly mechanical parts are not

on 100mil grids, including most relays and many

connectors (some of which expect slotted holes

in the PCB).

laeeq wrote: Is there a standard solution?

For a breadboard the simple answer is to solder

wires on the relay pins and plug those wires into

the breadboard as needed.

Posted: Thu Dec 04, 2008 1:02 pm

by philba

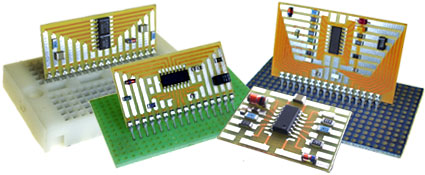

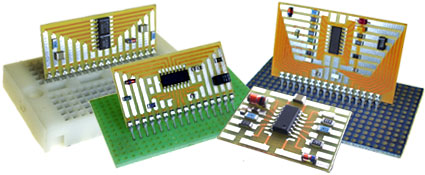

You can find relays that are 100 mil pitch but aren't compatible with solderless BBs because of the pin arrangement. I'd use perf board and header pins to build up an adapter that can plug into an SBB.

As big points out, this is a general problem. I've got home made PCB adapters that work quite well. I've made them for ICSP programming, several power supplies, 2.5mm power connector for Wall Warts, RS232 interfaces (including a max232), USB, char mode LCDs as well as several flavors of SMD chips. This makes putting together a quick test project on an SBB a real snap.

You can buy numerous SMD adapters that will work for this but I have no problem making my own. One brand is surfboard.

Posted: Fri Dec 05, 2008 9:48 am

by nav

I think it is a mistake to try to adapt everything to a solderless breadboard. Besides making an electrical connection, you also want to have mechanical stability, strain relief of cables, easy access to components, etc.

I often mount a solderless breadboard on another project breadboard which gives me a place to mount my power supply and other components which are not well-suited to a solderless breadboard. Plastic cafeteria trays turned upside down work well for this purpose. To mount a solderless breadboard on the tray you could use double-sided tape, but I just drill holes in the corners of the solderless breadboard and in the tray where I want to place it. Then I use a small length of wire to twist-tie the breadboard to the plastic tray. This makes it easily removable/repositionable. It's also very convenient having your whole project on a tray which you can easily carry and move around.

I'm on vacation right now, but next week I can upload a pic of what I'm talking about.

Edit: if you are talking about mounting the relay on a copper-clad pcb with .1" holes, then I would suggest enlarging nearby holes to accommodate your relay pins. Then secure it with solder and perhaps some hot glue. You also might be able to find a relay socket with a more compatible pin pitch.

Posted: Tue Dec 09, 2008 7:18 pm

by Dean Huster

I've modified countless components -- rotary, slide and toggle switches, jacks of all kinds, etc. -- for solderless breadboard mounting using gold-plated square pins if possible. Longer pins can be bent to hit the right holes. It was the 4P4T rotary switch that was the biggest headache, trying to get it set up so that each pin had its own strip.

Dean

Posted: Tue Dec 09, 2008 10:19 pm

by philba

I think it is a mistake to try to adapt everything to a solderless breadboard.

For fast prototyping, you can't beat a SBB. However, I can't imagine using one for anything that has to last more than a few days or endure more stress than sitting on a bench. and, anything with 110 or 220 VAC is a bad idea.

Posted: Wed Dec 10, 2008 3:51 am

by dr_when

I always get a kick out of analog guru Bob Pease's "rat nest" prototype circuits that use no breadboard. All the part leads are soldered to each other and the finished product looks like a tangle of parts and wires. He does not advocate the use of plug in proto boards for analog or high speed digital.

Posted: Wed Dec 10, 2008 5:27 am

by Dean Huster

I used to wire up large, complex digital and analog circuits for student use on those 8" x 8" Protoboards. Give a SBB a week or a month on the shelf and it develops all kinds of problems, especially if you us wire smaller than #22 or untinned wire. The worst thing I could do was wire up a circuit on an imported board. Bad news!

The best boards were from Global Specialities and E & L, both now a part of Interplex Electronics. I haven't even researched over the past 10 years to see what, if anything, is still available. I preferred the Global Specialties Protoboards because of their power strip geometry where the E & L brand was off by 0.05" in their spacing from the main breadboarding area. The nice thing about the boards from those companies is that they have a LIFETIME UNCONDITIONAL WARRANTY. If the board gets filled up with too many broken wires, loses spring, gets melted by overdissipated resistors or backwards power to ICs ... they replace it with a new one, no questions asked. Although they're more expensive than the Chinese versions, that warranty makes them more cost-effective in a school environment. I've gotten perhaps 50 boards replaced under the warranty.

Dean

Posted: Wed Dec 10, 2008 7:11 am

by Robert Reed

dr_when wrote:I always get a kick out of analog guru Bob Pease's "rat nest" prototype circuits that use no breadboard. All the part leads are soldered to each other and the finished product looks like a tangle of parts and wires. He does not advocate the use of plug in proto boards for analog or high speed digital.

In the world of Amateur Radio, that type of construction is known as "Dead Bug" or "Ugly" construction. The advocates say in many instances, they have superior performance to the finished circuit board.